- +91 281 2311431

- info@ominternationals.com

- +91 98246 03676

- |

- info@ominternationals.com

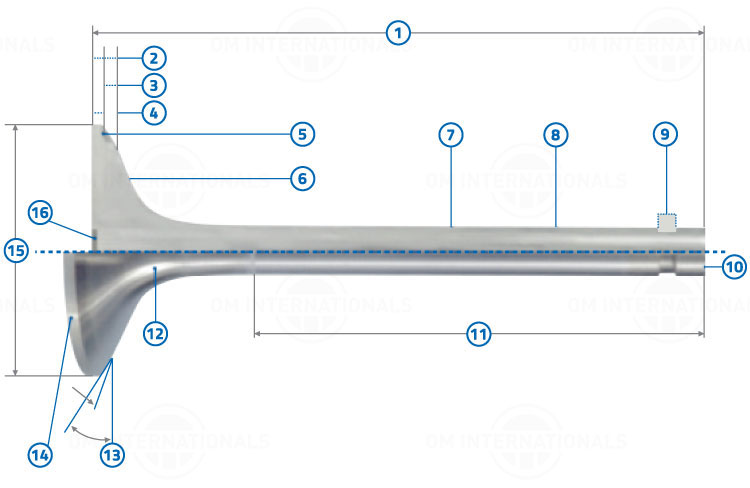

| 1 | Total Length |

| 2 | Total Valve head thickness |

| 3 | Seat Height |

| 4 | Height of valve seat face |

| 5 | Seat Mourning |

| 6 | Valve Head |

| 7 | Skirt diameter |

| 8 | Valve stem |

| 9 | Groove diameter |

| 10 | End face of stem (hardened) |

| 11 | Grinding length |

| 12 | Throat |

| 13 | Valve seat angle |

| 14 | Head surface |

| 15 | Head diameter |

| 16 | Culotte |

10000 pieces per month

*Believe in Quality not Quantity.

Mono-metallic valves are only made from one material. For this, one material is chosen that is suited to both requirement profiles, namely high heat resistance and good sliding properties.

Bimetallic valves enable material combination of a highly heat resistant agent (headpiece) with a skirt material which can be hardened on the one hand (skirt end) and also has good sliding properties for valve guidance. The materials are combined through friction welding.